Projected AI

Projected AI: Real-Time Detections and Assembly Instructions – Live from Automate 2025

The future of industrial automation has arrived—and it’s being projected in real time.

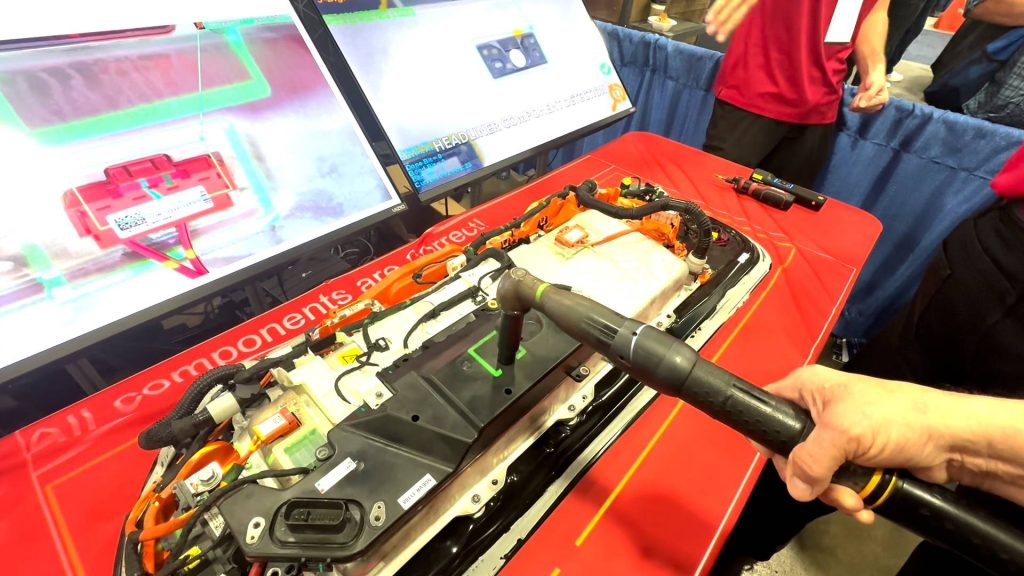

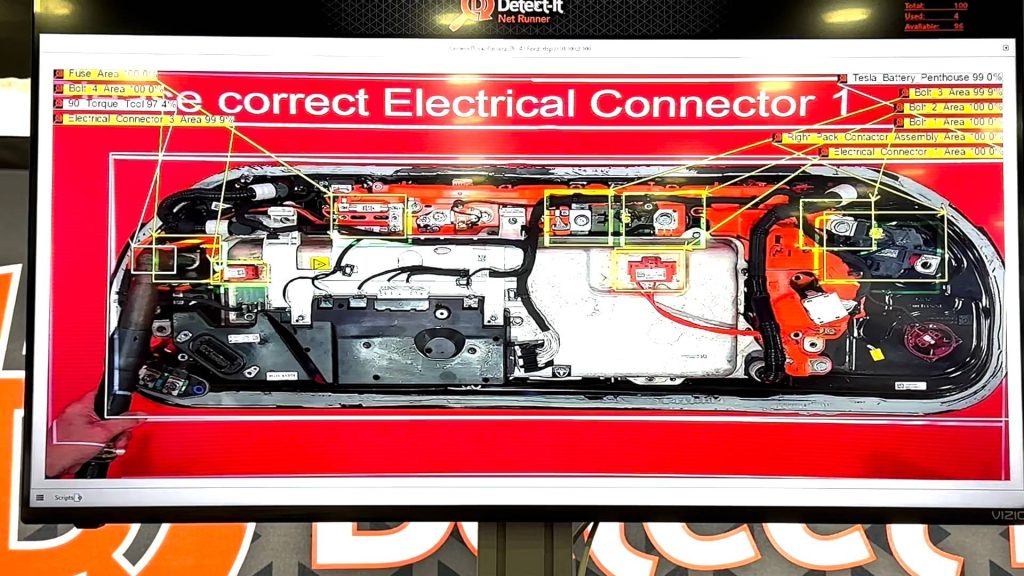

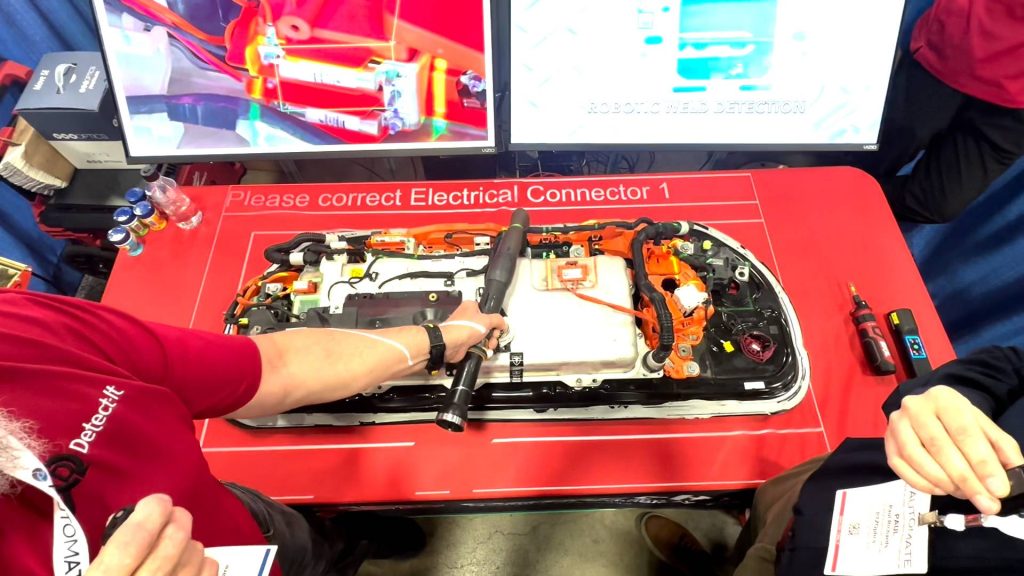

At Automate 2025, PTZOptics and Detect-IT showcased a cutting-edge solution that combines AI-powered computer vision, projection mapping, and robotic camera control to transform traditional manufacturing workflows. The result? Projected AI—a system that visually guides operators with live overlays, ensuring precise part assembly and streamlined quality control.

🧠 What Is Projected AI?

Projected AI uses a pair of intelligent PTZ cameras to identify, analyze, and project information directly onto manufactured parts:

Camera 1: Scans and identifies parts as they arrive on the assembly line, tracking position and orientation.

Camera 2: Zooms in for detailed inspections, analyzing key features and confirming visual accuracy using Detect-IT’s computer vision software.

These cameras work together to drive a projector system that overlays live instructions and detection boxes directly on the part itself—not just on a monitor. The operator sees what to do, where to look, and what’s wrong (if anything) in real time, right on the object.

⚙️ How It Works

Detection & Orientation

The first PTZ camera, mounted above the production area, identifies incoming parts and determines how they’re positioned.Precision Analysis

A second PTZ camera zooms into specific regions of interest, enabling high-resolution inspections or verifications (e.g., checking for missing components or misalignments).Visual Overlay

A projector, linked to the AI system, casts detection boxes, arrows, alerts, or step-by-step instructions onto the actual part—not a screen—guiding human operators in real time.Live Feedback

Operators receive instant visual cues that help them complete tasks correctly, reducing cognitive load and increasing throughput.

🚀 Why It Matters

In high-mix, low-volume environments—or anywhere where human-in-the-loop systems are essential—Projected AI offers major advantages:

✅ Reduced error rates

✅ Faster onboarding of new employees

✅ Consistent assembly processes

✅ Increased throughput and efficiency

✅ Scalability with up to 25 cameras per system

This isn’t just an inspection system—it’s a visual guidance solution designed for modern smart factories.

🌐 The Convergence of AI, Vision, and Projection

This demo captured a major trend shaping the future of manufacturing: the convergence of AI + Computer Vision + Projection Mapping. Together, these technologies create adaptive, intelligent environments where machines support human workers—not replace them.

By combining the mobility of PTZ cameras with the intelligence of Detect-IT’s software and the intuitiveness of real-world overlays, manufacturers can now deliver the right information at the right place, at the right time.

📦 Get Started

Want to bring Projected AI to your facility?

Download the Detect-IT Toolkit

Submit a video of your product for a free proof of concept

Learn more at ptzoptics.com/computer-vision