Detecting Manufacturing Defects with Computer Vision: A Step-by-Step Guide

Manufacturing defects can be costly — not just in terms of money, but also in time and reputation. What if you could stop those issues before they ever left your factory? With the power of AI and computer vision, real-time quality control is more accessible than ever.

In this post, we’ll walk you through how to set up a camera system to automatically detect defects on your production line using PTZOptics cameras and Detect-IT — a no-code software solution designed for manufacturers who want smarter quality control.

Step 1: Choose the Right Camera for Your Product

Before diving into the tech, start by understanding the size of the product you need to inspect. This determines which PTZOptics camera model is best for your workflow. A good rule of thumb: your product should fill 50–75% of the camera’s frame. This ensures your AI has the detail it needs for accurate detections.

Many manufacturers need to inspect small sub-assemblies within larger products. That’s where PTZ (pan-tilt-zoom) cameras shine — you can zoom into specific components, revealing enough detail for high-confidence detection.

A major advantage of PTZ cameras is their ability to recall saved PTZ Presets. These presets let you quickly switch between multiple inspection zones along your production line. Detect-IT supports preset recall, so your inspection workflow can include multiple angles and areas with the click of a button.

Use the PTZOptics Zoom Calculator to figure out the ideal camera distance for your setup. With optical zoom levels ranging from 12x to 30x, you can get up-close visuals from practically any position in your facility.

Need help getting started? Send us a sample video, and we’ll run a free proof-of-concept demo using Detect-IT on your actual workflow.

Step 2: Connect Your Camera for Test Footage

Once you’ve selected your camera, it’s time to install and connect it. PTZOptics cameras support Power over Ethernet (PoE), so with a single network cable, you get power, video, and control — simplifying installation.

Camera placement is key. Mount your camera using ceiling, wall, or pole mounts to get the best angle for visibility. If you can clearly see the part with your eye, the AI can detect it — it’s that simple.

To maintain consistency, install the camera in a fixed position. This ensures the AI is trained on the exact view it will analyze in real time. Once your camera is installed and connected to your network, install the Detect-IT software on your local machine or server and move on to the fun part.

Step 3: Train Your AI for Defect Detection

This is where your system becomes intelligent.

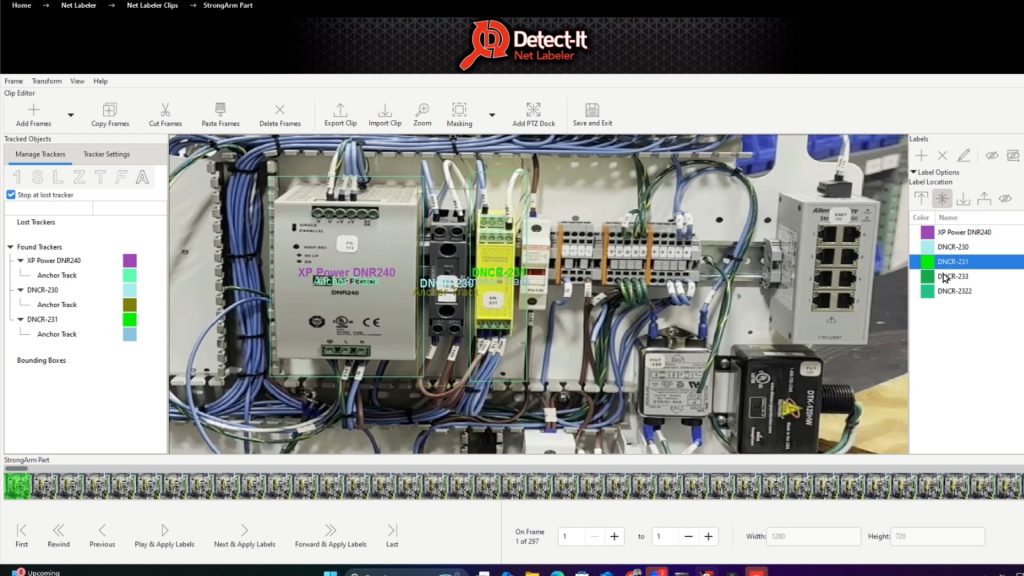

Record test footage of your production line and begin labeling examples of good products and defects. Detect-IT lets you train a custom neural network based on your specific products — no generic models here.

Labeling is fast and efficient thanks to Detect-IT’s automated labeling system. As your model learns, you can train and retrain it until it’s dialed in. You’re building a custom detection engine tailored to your manufacturing process.

Once trained, your AI model can interact with external systems via IP protocols and even trigger alerts or sort products based on visual inspection results.

Step 4: Deploy for Real-Time Defect Monitoring

With your model trained, it’s time to put it to work.

Using the Detect-IT Net Runner, your system can now provide real-time analysis of your production line, flagging defects and inconsistencies as they appear. PTZ camera presets make it easy to focus on critical inspection zones — whether it’s a DualLock fastener inside a door frame or a circuit board sub-assembly.

This real-time detection means:

Fewer missed defects

Reduced human error

Higher consistency

Actionable data for process improvements

Each deployment of Detect-IT can support multiple PTZOptics cameras (depending on your computing resources), allowing you to monitor an entire line — or multiple lines — from one centralized system.

Go Remote with PTZOptics Hive

Want remote visibility into your quality control process?

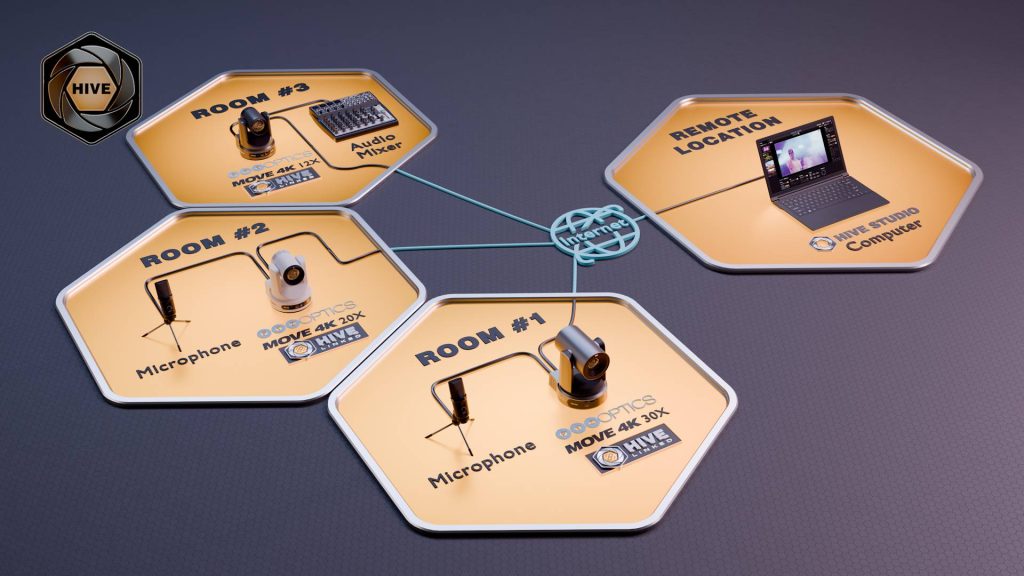

With PTZOptics Hive, you can monitor and manage all your cameras through the cloud. Whether you’re at another plant or halfway across the world, Hive lets you:

View live camera feeds

Adjust PTZ settings

Manage presets and configurations

Review inspection media — all through a secure browser-based interface

Scalable, flexible, and easy to manage, this is modern manufacturing at its best.

Ready to Get Started?

Bring AI-powered defect detection to your factory floor today.

Fill out the form below and let us build a proof-of-concept tailored to your needs. Just describe what you’re trying to detect, and we’ll handle the rest.

Prefer a live walkthrough? Schedule a demo and see how PTZOptics + Detect-IT can revolutionize your quality control process.