AI Camera Inspection System

Smarter Quality Control with AI: PTZOptics + Detect-IT Demo from Automate 2025

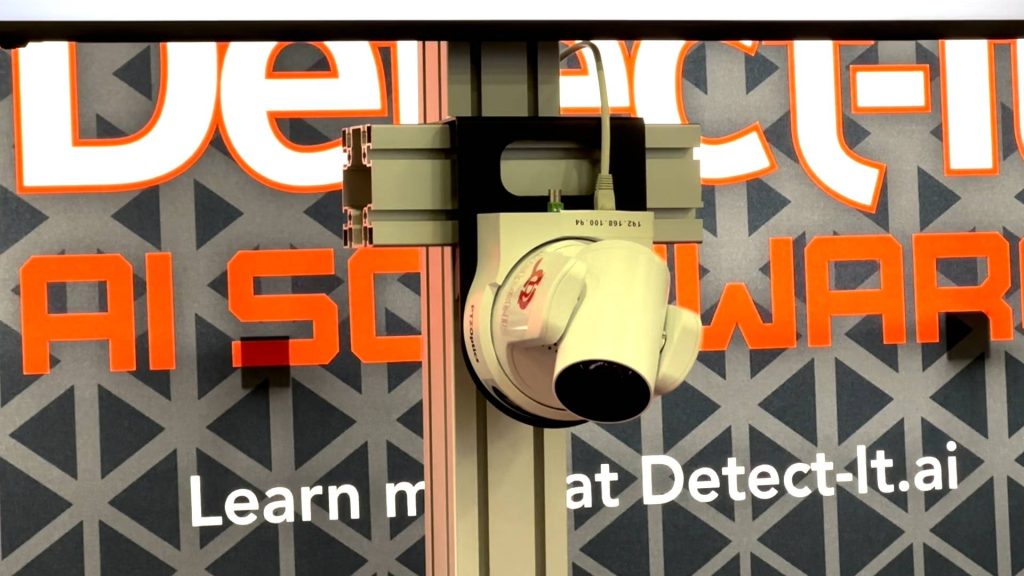

At Automate 2025, we shared a look at how manufacturers can streamline their quality control process using an AI inspection camera system powered by PTZOptics and Detect-IT. The goal is simple: give factory teams better tools to inspect parts, document compliance, and scale inspection processes—without complex programming or expensive infrastructure.

This system combines two powerful technologies:

PTZOptics cameras that offer flexible, precise visual coverage of your production line

Detect-IT, a no-code AI vision platform designed for fast deployment and intuitive defect detection

Let’s walk through how it works and why it matters.

🎥 Visual Inspection That Scales

Many modern factories have hundreds of cameras installed across their production lines. Fixed cameras serve a purpose—but PTZ (pan-tilt-zoom) cameras introduce new flexibility. A single PTZOptics camera can store up to 255 preset positions, meaning it can quickly move from one inspection area to another using a programmed “flight path” or PTZ Preset Tour.

This is a huge cost-saver: instead of installing multiple static cameras, manufacturers can use one PTZ camera to cycle through dozens of checkpoints. While it’s true that a PTZ camera can’t provide simultaneous views, the tradeoff is in cycle time—the speed at which the camera returns to each preset. For many workflows where parts need to be inspected every few seconds or minutes, this is more than sufficient.

Of course, in ultra-fast environments, it may still make sense to use fixed cameras alongside PTZ cameras to balance coverage and speed.

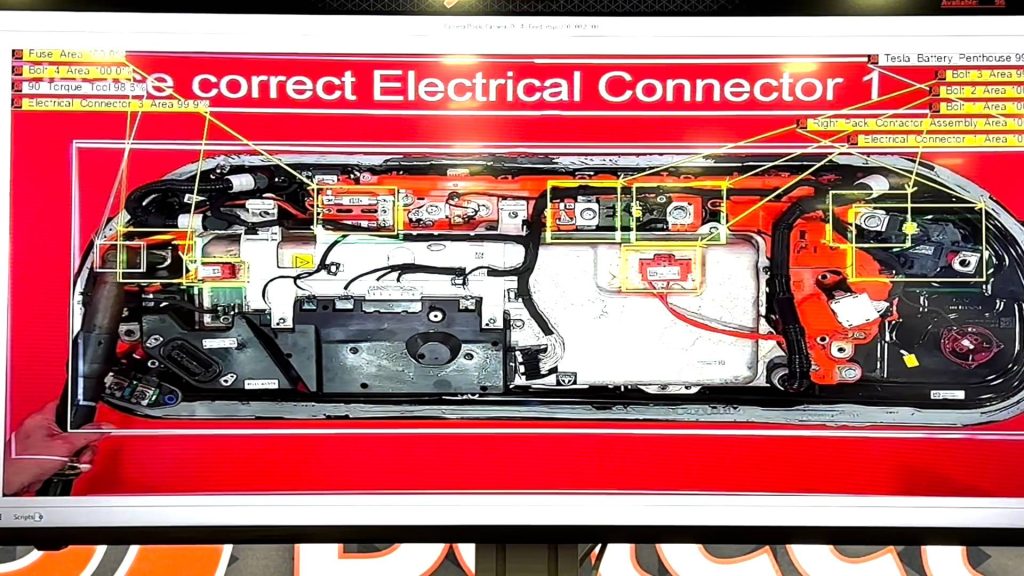

🧠 No-Code AI for Everyone

What really sets this solution apart is the Detect-IT platform. You don’t need to be an AI engineer to use it. Detect-IT is designed for manufacturers, QA teams, and integrators to:

Upload sample images of their products

Label defects and pass/fail conditions

Train a computer vision model in a few clicks

Deploy it live on the production line for real-time detections

No programming. No expensive consultants. Just results.

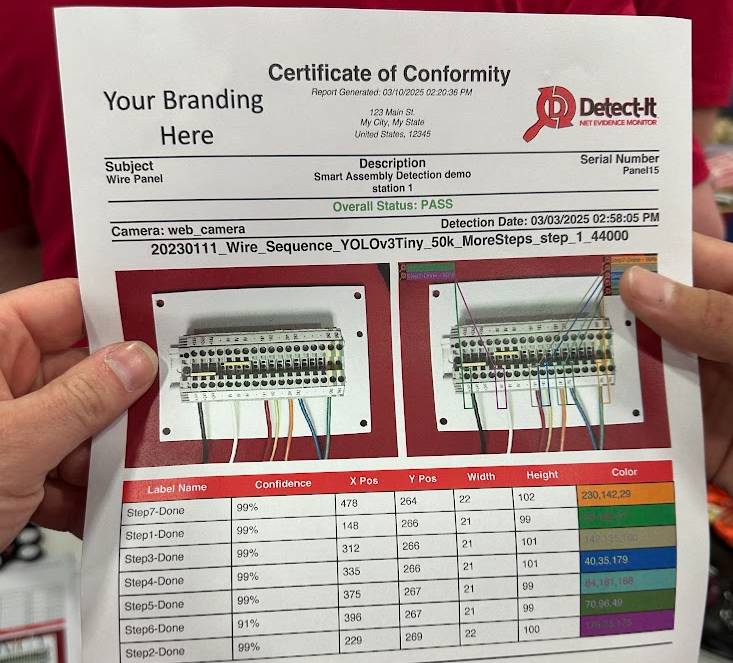

📄 Built-In Compliance with Evidence Builder

Beyond real-time defect detection, Detect-IT also helps with compliance tracking—a growing need in global manufacturing.

The platform includes a tool called Evidence Builder, which automatically compiles the results of each inspection into a Certificate of Compliance (CoC). These CoCs can be exported as PDFs and include:

Timestamped inspection results

Photos (and optionally videos)

Operator IDs and part IDs

Integration into factory MES systems

This is especially valuable in regions like the European Union, where new laws now require proof of sourcing and production. Even though the U.S. tends to adopt these types of regulations later, forward-thinking manufacturers are already leveraging this capability to save time, reduce errors, and maintain traceable records across all production steps.

🔁 Scalable Across the Floor

Detect-IT supports deployments of up to 25 PTZ cameras per system, making it ideal for factories looking to scale without adding a large IT burden. Each camera can be configured independently or in coordination, using Detect-IT’s central dashboard to manage all detections, alerts, and logs.

Whether you’re running a small pilot line or a full-scale facility, this solution grows with you.

🚀 What You’ll See in the Live Demo

Filmed on-site at Automate 2025, our demo highlights:

Live inspection of manufactured parts using AI

PTZ camera coverage of dynamic inspection zones

How to train and deploy a detection model

Real-time alerts and data collection

Overview of Evidence Builder and automated documentation

Watch the full demo and explore how this practical AI inspection system can make your factory more efficient and compliant.